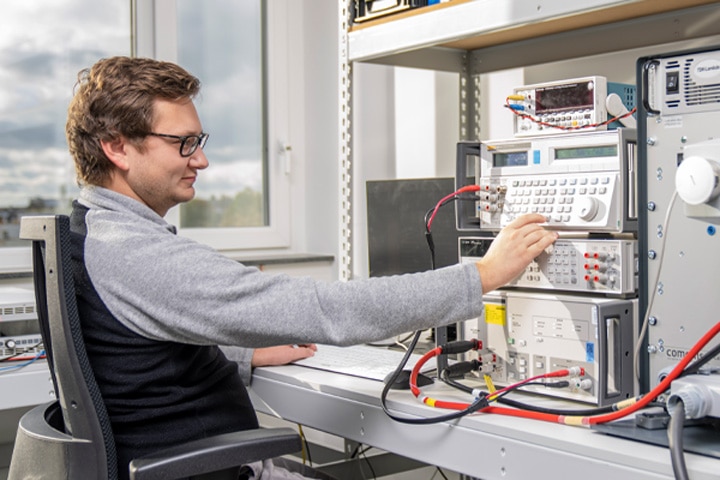

Experience best-in-class BMS testing with products from comemso, a leader in battery management system testing for more than 10 years. Our Battery Cell Simulator (BCS) enables you to optimize, validate and ensure the safety and robustness of your automotive Battery Management System (BMS). Increase the range of your EV, optimize battery cell health and aging, and streamline your BMS testing procedure through active or passive balancing simulations with the state-of-the-art (BCS) designed for BMS Hardware-in-the-Loop validation (BMS HiL) was developed.

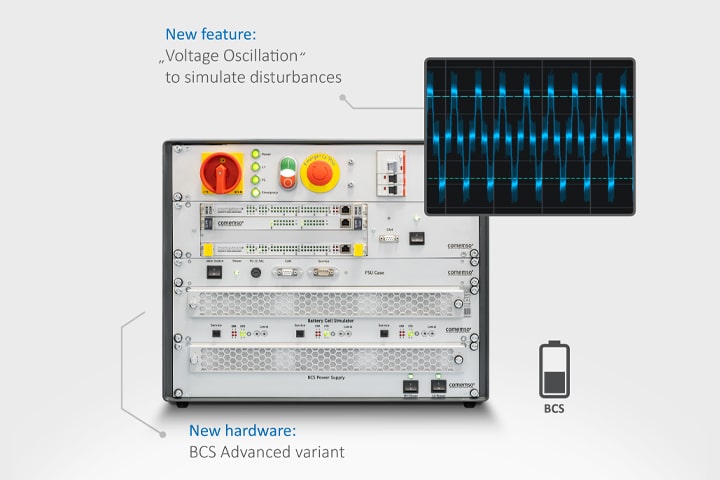

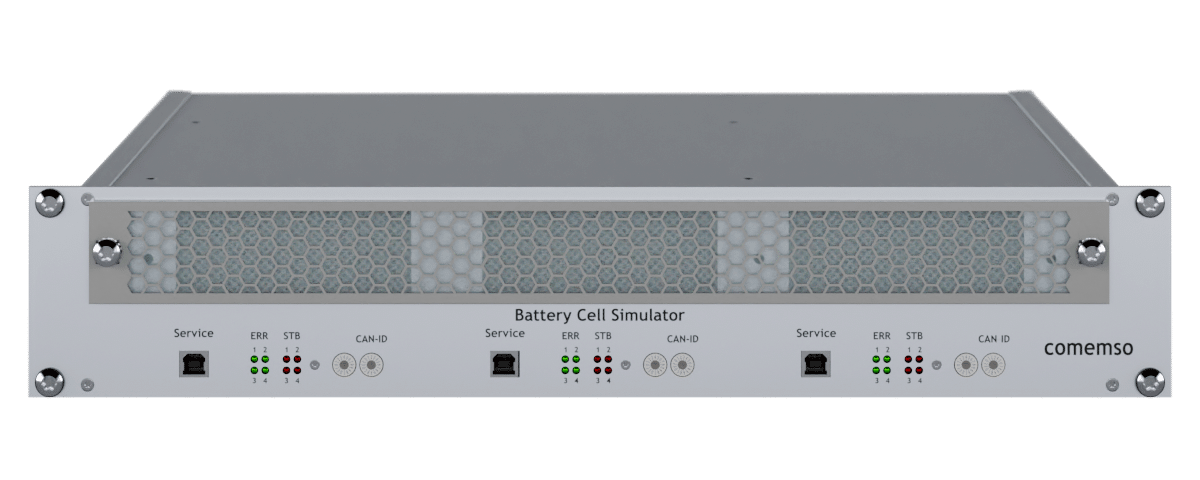

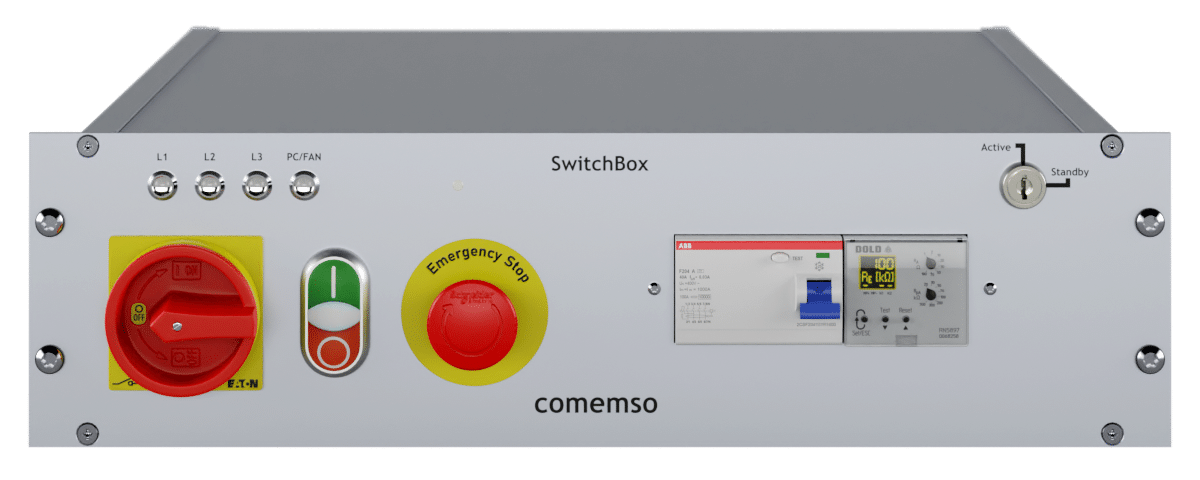

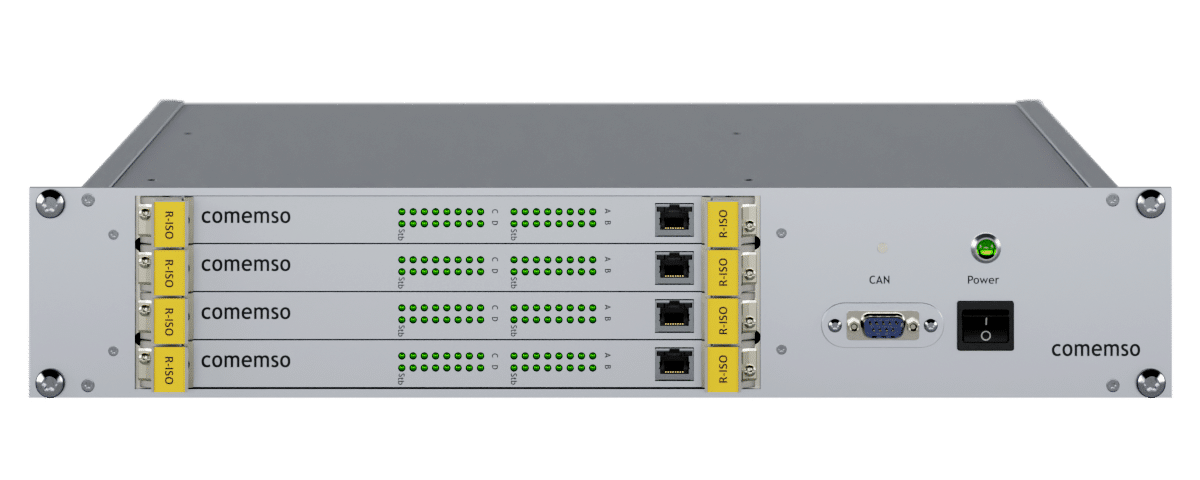

Comemso offers a diverse range of modules for BMS testing with scalable variants and diverse functions to meet different BMS validation needs. Our modular Battery Cell Simulators offer tailor-made solutions, combining standard components for maximum flexibility in implementing different sized systems to meet customer requirements.

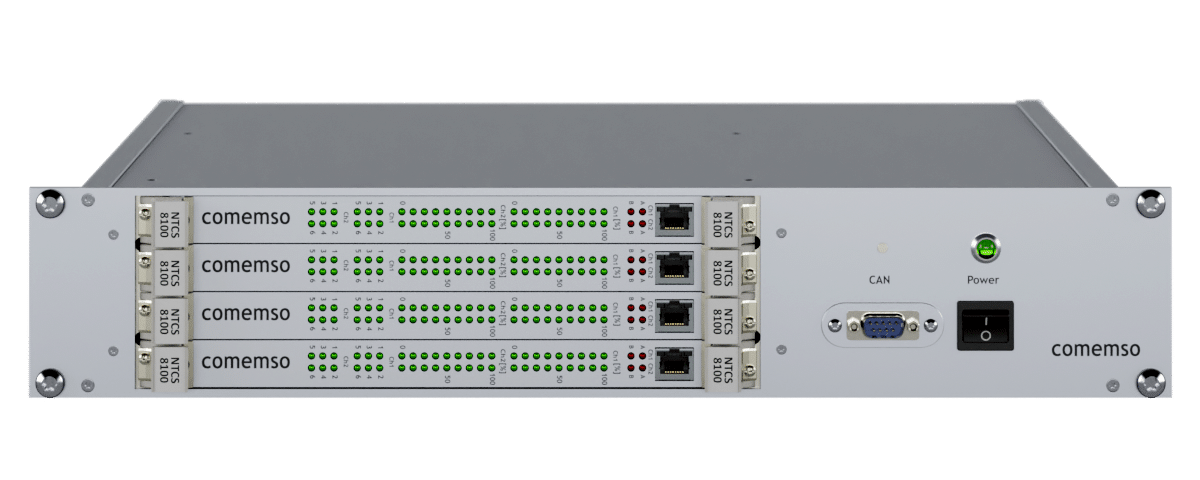

Our product range includes portable benchtop systems from 12 to 36 cells, ideal for chipmakers, start-ups or entry-level research into automotive Battery Management System testing. We also offer mid-size systems from 24 to 60 cells, aimed at designers of BMS or active and passive balancing systems. For larger requirements, we recommend large racks with more than 204 cells, which can be customized according to customer specification.

All comemso systems enable comprehensive BMS testing from cell level to pack level to ensure the development of safe, energy efficient and durable products with accurate and reliable range information. Regardless of their size, our systems can be configured as End-of-Line (EOL) variants for continuous operation and the highest precision (less dynamic) in battery cell emulation with high accuracy.

„At TI, we know having the right tools and support makes innovation possible. Our broad portfolio of devices for battery management systems coupled with comemso’s proven results and accuracy with their battery cell simulator helps accelerate design time. comemso offers the ability to test and measure your system on a cell level with high precision.“

„At TI, we know having the right tools and support makes innovation possible. Our broad portfolio of devices for battery management systems coupled with comemso’s proven results and accuracy with their battery cell simulator helps accelerate design time. comemso offers the ability to test and measure your system on a cell level with high precision.“