The BMS Tester Trusted by Leading BMS Test and Development Engineers

Why Reliable BMS Testing is Important

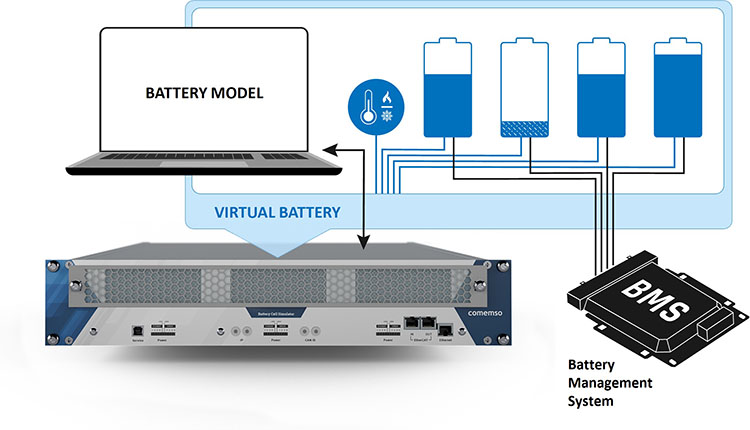

Your Battery Management System (BMS) is at the core of ensuring battery safety, efficiency, and lifespan in your electric vehicle’s battery. However, unreliable BMS functional testing can lead to costly delays, safety risks, and lost trust. With the right BMS tester, you can avoid these issues and stay ahead of the curve.

Every BMS is unique, but the challenges remain the same:

- How do you ensure electrical safety and performance without wasting time or money?

- How can you simulate real battery conditions accurately?

- Can your testing process keep up with the pace of innovation?

With comemso’s advanced BMS tester, you can confidently optimize your testing process, achieving precise and efficient BMS testing. Discover how our solution helps you meet these challenges head-on and elevate your testing game.